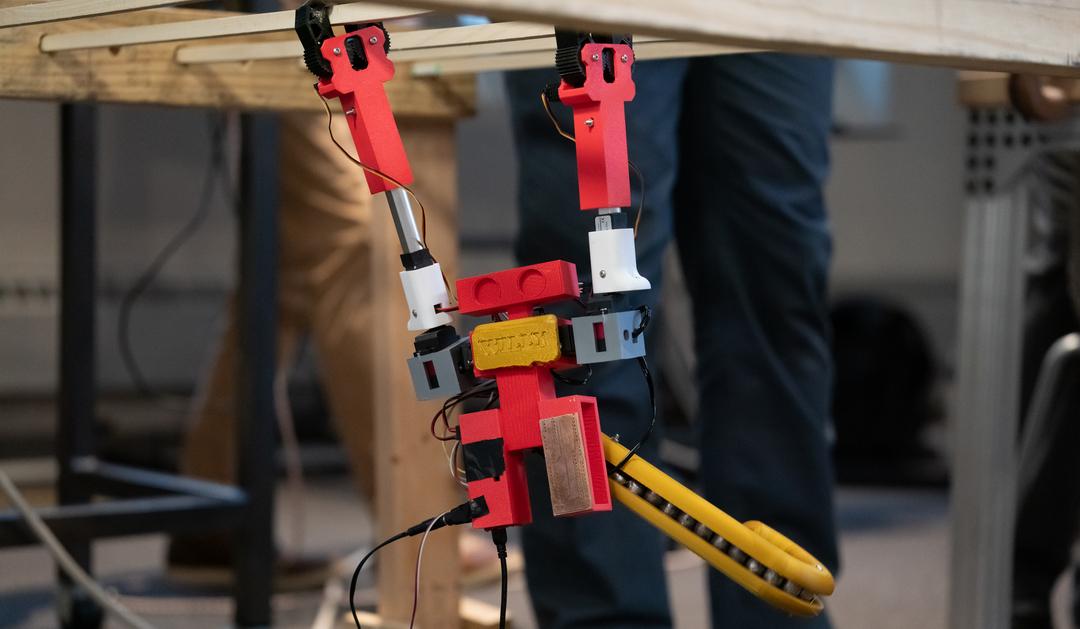

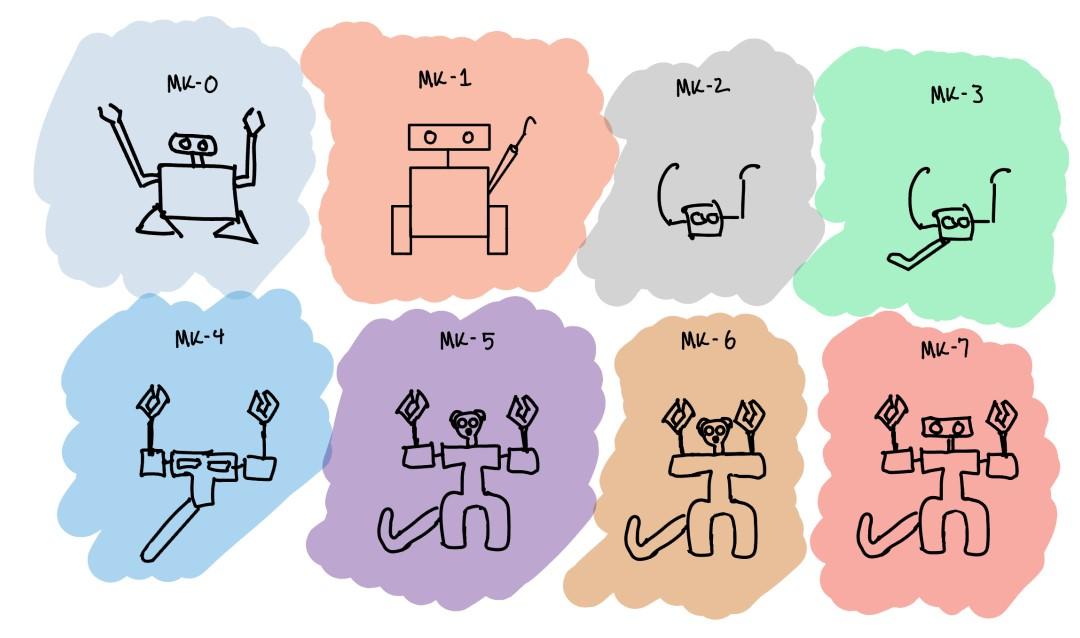

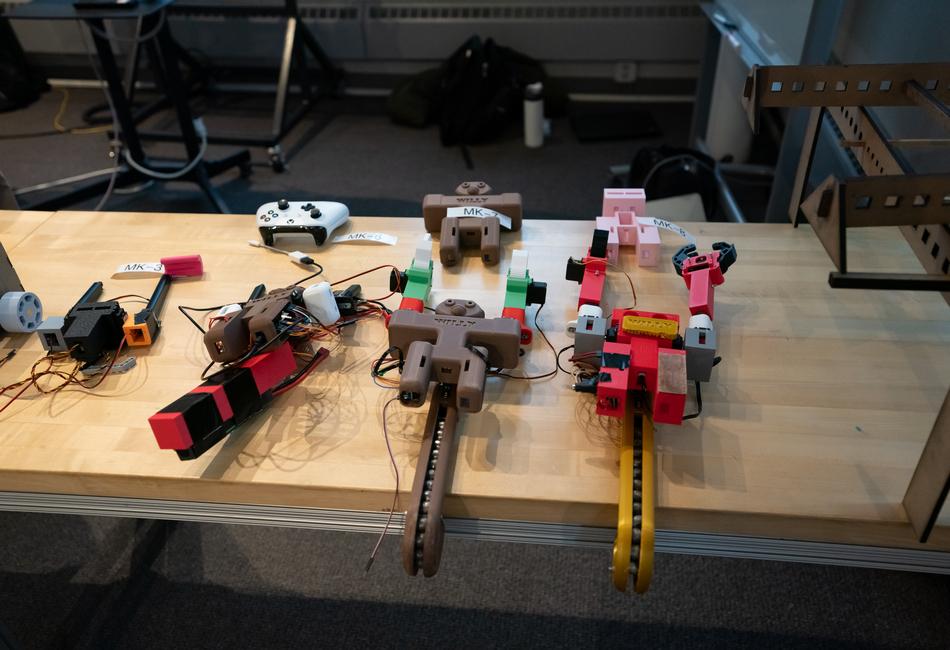

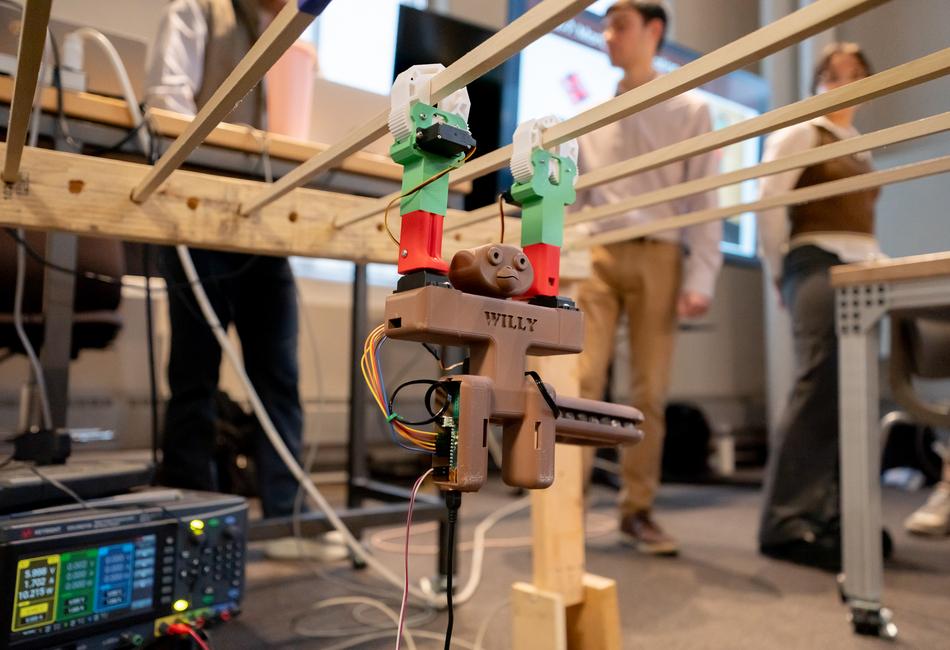

Cosse, who is pursuing his Ph.D. at Lehigh, and Macchia, who is pursuing a master’s in mechanical engineering at Lehigh, will continue working on Willy. When the robot is finished, it’s expected to be four-and-a-half feet tall, be three times faster and could incorporate other interactive elements, like a controller that allows visitors to activate it.

“With the Design Labs, the goal is to have tools there so students can be creative and develop designs to respond to their ideas,” DeWeerth said. “They can be makers, and making is a central part of our university strategy.”

Robotics at Lehigh

Robotics has become a popular area of study at Lehigh in recent years. The Autonomous & Intelligent Robotics Lab (AIR Lab) opened at the Mountaintop Campus in 2021 and several student clubs focusing on various areas of robotics have started since then, DeWeerth said.

The AIR Lab is a joint research group composed of faculty and students studying relevant areas of robotics, including robot control, machine learning, manipulation, aerial robotics and autonomous driving. The AIR Lab is for advanced researchers and those looking for open space to test prototypes that require a lot of room, such as flying robots and blimps, DeWeerth said.

The Freed Family Robotics Design Studio will serve as the new hub for robotics clubs and provide a space for undergraduate students, regardless their level of experience, to explore robotics.

“The Design Labs play this amazing role of resourcing all these different kinds of projects, from complex game-changing robotics research, to a student wanting to build a small device that does something interesting,” DeWeerth said. “You have this whole range where they provide space, they provide materials and supplies, and most important, they provide advice, guidance and mentoring.”

The new studio creates opportunities students wouldn’t have had before because they didn’t have the resources, said Kelly Zona, manager of the electronics and robotics studios at Lehigh’s Design Labs.

“I think it’s two-fold — if students have an idea, they can come down and see what we have to offer. It also helps students, like those in our clubs, continue with what they are doing,” Zona said.

Zona and Brian Slocum, director of the Design Labs, also are in the process of creating a curriculum for the lab that would go over the basics of actuators, sensors, mechanisms and kinematics. It will be designed for those without any previous knowledge of or experience with robotics.