In the dynamic setting of Lehigh’s Design Labs, Bryce Cavey ’20 was captivated by the intricate task of chassis welding. Delving deep into the fabrication process, he soon found himself leading chassis construction for the student-run Formula SAE team’s single-seat race car.

Could the same hands fine-tuning aerodynamics for speed one day help design starships?

That is the path Bryce Cavey ’20 navigated—from the Formula SAE (FSAE) team to the pioneering platforms of SpaceX.

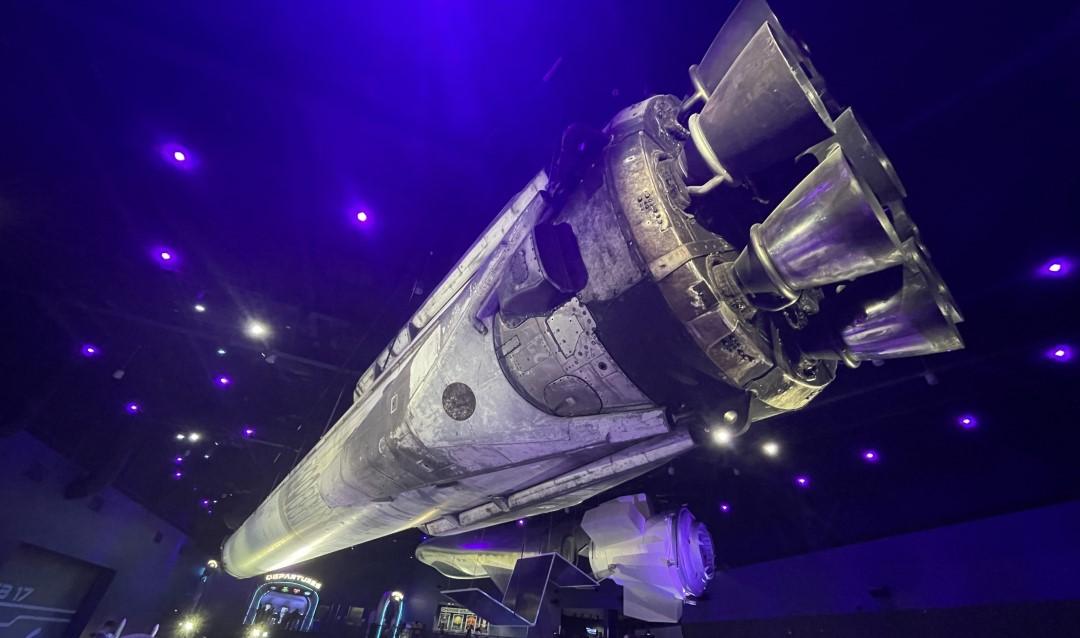

Fueled by his passion and expertise in metal fabrication, Cavey, a mechanical engineering major with a computer science minor, secured a position at SpaceX after graduating from Lehigh. There, his designs contribute to the development of SpaceX’s Starship rocket.

As a tooling engineer at SpaceX, Cavey leverages his expertise in automated welding machinery—skills honed on the Lehigh FSAE team. The club, which is composed of about 30 engineering and business students, is where Cavey's passion for welding took shape.

"I joined the FSAE team in my sophomore year, and explored a spectrum of engineering facets, but welding was the one that really sparked my curiosity," Cavey shared.

His breakthrough moment as a student came in the Wilbur Powerhouse, where through the support of the Design Labs he became captivated by the intricate task of chassis welding. Delving deep into the world of welding, he soon found himself leading the chassis construction for the team's single-seat race car.

Cavey credited his time with the FSAE team and the hands-on resources of the Design Labs as crucial in helping him land his dream job at SpaceX.

"The Design Labs provided me with access to an array of tools, from 3D printers to TIG welders," he said. "We didn't just design; we also built, tested and learned from our failures."