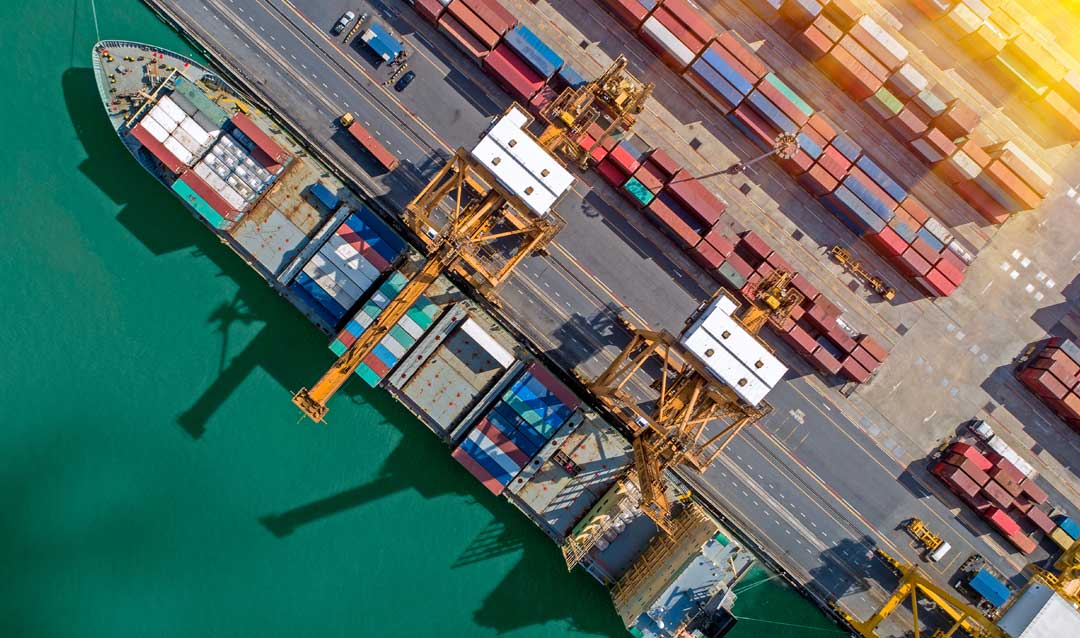

Q. The COVID-19 pandemic has shaken up the global economy. Can supply chains survive?

A. Absolutely. Businesses will find ways to adapt to the changing environment. This is the new normal that we can all adapt to.

Q. How do you anticipate global business relationships changing?

A. Global supply chains will likely want more transparency. There will be a need to understand where the product is sourced. There will likely be a need to create some redundant supply chains to handle quick shifts in demand, sort of the 80/20 rule where you can source 80% for low cost and 20% for quick response.

Q. Will companies alter their supply chains to reduce dependence on China for goods and materials, given the wide production stoppages there?

A. Related to the previous point, the majority of low-cost, constant demand items can be sourced from across the globe, but quick response with volatile demand can be sourced more locally, perhaps in this country.

Q. Empty grocery store shelves certainly reflect panic shopping, but do they expose problems in the food supply chain as well?

A. I do not think so. You can never predict panic demand or should you store inventory for panic demand. It would be too costly. Now, there does need to be some “retooling” of the supply chain that used to serve restaurants and grocery stores to switch to only serving grocery stores, but companies can make that shift.

Q. How does the current situation during the COVID-19 pandemic compare to past disruptions to the supply chain, including natural disasters?

A. COVID-19 is a Black Swan event—an example of something that is not predictable and can have a huge impact. Natural disasters you can plan for, like hurricanes. Other Black Swan events include 9/11 (reduced demand), the 2008 financial crisis (reduced demand) and the 2011 Japanese Tsunami (reduced supply). COVID-19 affected both supply and demand. Also, it has a global impact. It did not matter if your supplier is in China and in Italy; they both would be affected.

Q. Do you anticipate that U.S. businesses will look to more local sources of goods and materials in an attempt to stabilize their supply chains?

A. Yes, absolutely.

Q. How can U.S. businesses better prepare for the future, once the current crisis has ended?

A. Share information along the supply chain. Understand who your suppliers are and who their suppliers are. Look for ways to work together so you will all survive.

Zaccharia addresses “Supply Chain Resilience” in a webinar that can be seen here.