Stronger structures from the ground up

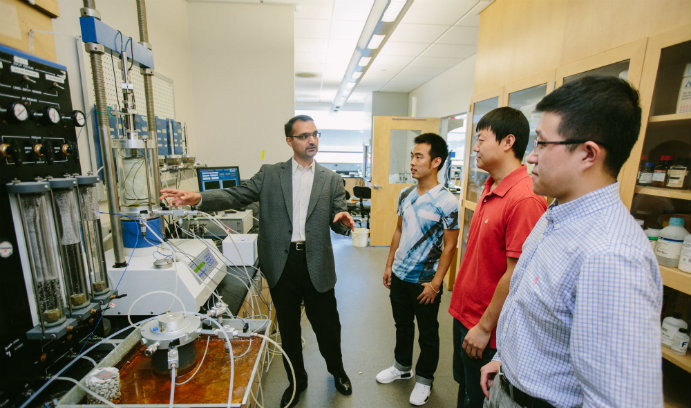

Professors Muhannad Suleiman (pictured here, left), Bryan Berger and Derick Brown recently received an 18-month grant from the National Science Foundation to explore silicatein’s potential as a soil strengthening agent.

A structure, Muhannad Suleiman likes to observe, is only as strong as the soil on which it stands. A bridge or skyscraper can be built with the best materials and construction techniques, but it won’t withstand earthquakes or other natural hazards if it rests on weak or loose soil.

Suleiman, an associate professor of civil and environmental engineering, is proposing to provide structures with a firmer, more environmentally friendly soil foundation by enlisting the aid of an enzyme found in deep sea sponges.

The enzyme, called silicatein, has shown promise in precipitating the formation of flexible calcite (calcium carbonate) in soils. The calcite acts to strengthen soil by causing its tiny particles to cement together.

Suleiman and two other faculty members—Bryan Berger, associate professor of chemical and biomolecular engineering, and Derick Brown, associate professor of civil and environmental engineering—recently received an 18-month grant from the National Science Foundation to explore silicatein’s potential as a soil strengthening agent.

Engineers have traditionally strengthened weak or loose soil by compacting it or by grouting it with cement, says Suleiman, whose specialty is geotechnical engineering. This helps soil resist the loading, or forces, imposed by natural hazards.

More recently, Suleiman and other researchers have had success using the microbes, or bacteria, that occur naturally in soil to precipitate the formation of calcite, which acts as a cementing agent. But this process, called microbial induced carbonate precipitation (MICP), has limitations. MICP yields a brittle calcite bond and also produces ammonia, a hazardous material. And the microbes, which measure 1 to 2 microns across, are too large to penetrate the very small pores that are typical of clayey and silty soils.

These drawbacks, the researchers wrote in their NSF proposal, limit the types of soil to which MICP can be applied and the ability of soil to withstand the shear forces of earthquakes. They also limit the potential for MICP to be used in supporting structural foundations and in mitigating liquefaction, which occurs when soil becomes saturated and loses its strength and stiffness.

By contrast, says Suleiman, silicatein promises to produce a stronger, more flexible bonding of soil particles. And because the enzyme is much smaller than a microbe, it could be potentially used in much finer soils.

Suleiman decided to test silicatein in soil engineering last year when he and his research team came across an article that had been published in 2013 by researchers from Johannes Gutenberg University and the Max Planck Institute in Germany. Writing in Science, the group reported the creation of a new synthetic material that was made of silicatein and calcite, characterized by a “rubber-like flexibility” and inspired by the spicule, a structural element of the sea sponge.

After reading the Science article, Suleiman spoke with Brown, who urged him to contact Berger. “We thought this could be the next step of our research,” Suleiman said. “I didn’t know that Bryan was already working in this area.”

Berger was seeking to employ silicatein to synthesize metal oxide nanoparticles, which are used in catalysts, separations and other applications. With three other faculty members—Steve McIntosh and Mark Snyder of chemical and biomolecular engineering and Chris Kiely of materials science and engineering—Berger had secured an Accelerator Grant from Lehigh to scale up the biomanufacturing of functional, nanostructured materials.

The current methods of synthesizing many metal oxides, says Berger, require heat, high pressure and chemical solvents that are expensive and toxic. Silicatein overcomes these drawbacks.

“Silicatein can mineralize metal precursors into crystalline metal oxides at room temperature and pressure and using only water,” says Berger. “It’s a much cheaper and more environmentally friendly method than current methods.”

In their NSF project, Suleiman, Berger and Brown are seeking to scale up the production of silicatein in the lab. They are also attempting to engineer silicatein so it provides the optimal bond properties between soil particles, enabling the soil to remain stable when subjected to natural hazards. Another goal of the project is to achieve uniform deposition and transport of the enzyme through soil.

Suleiman also has a 2016 Faculty Innovation Grant (FIG) from Lehigh in which he is seeking to improve soil strength and bonding with silica.

“We’re attempting to hit a similar target with two different processes,” he said.

The latest award is Suleiman’s fifth from NSF in eight years. He is also working with a biologist in Qatar to use bacteria to improve soil’s performance under sand storm conditions. Brown and Panos Diplas, department chair of civil and environmental engineering, are also collaborating on the project, which is funded by the Qatar National Research Fund (QNRF).

Photos by Christa Neu

Posted on: