Owl-inspired Design Cuts Wind Turbine Noise

By suppressing the noise of its wings at certain sound frequencies, says Justin Jaworski, the owl is able to fly soundlessly and surprise its prey. (Image courtesy of iStock / Wendi Evans)

Many species of owl are able to hunt without being heard by their prey by suppressing the noise of their wings at sound frequencies above 1.6 kilohertz (kHz)—outside the range to which human hearing is most sensitive.

A team of researchers is studying the acoustics of owl flight in an effort to pinpoint the mechanisms that achieve this virtual silence. Their goal is to improve man-made aerodynamic design of wind turbines, aircraft, underwater vehicles and even automobiles.

The team includes Justin W. Jaworski, assistant professor of mechanical engineering and mechanics at Lehigh.

Through physical experiments and theoretical modeling, the team has succeeded in using the downy canopy of owl feathers as a model to inspire the design of a 3D-printed wing attachment that reduces wind turbine noise by a remarkable 10 decibels without impacting aerodynamics.

The researchers have further investigated how their design can reduce roughness as well as trailing-edge noise. The trailing back edge of a wing or blade, says Jaworski, is the predominant source of noise generated by an object passing through the air. Trailing-edge noise is prevalent in low-speed applications.

The ability to reduce wing noise has implications beyond wind turbines, as it can be applied to other aerodynamic situations such as the noise created by air seeping through automobile door and window spaces.

The group is publishing its results in two forthcoming papers – “Bio-inspired trailing edge noise control” in the American Institute of Aeronautics and Astronautics Journal and “Bio-inspired canopies for the reduction of roughness noise” in the Journal of Sound and Vibration.

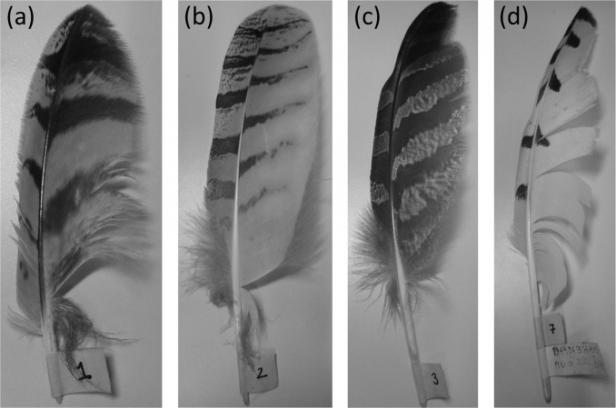

The researchers—from Lehigh, Virginia Tech, Florida Atlantic University and the University of Cambridge—looked at the velvety down that makes up the upper wing surface of many large owls. This physical attribute, which is unique even among birds, contributes to owls’ noiseless flight. As seen under a microscope, the down consists of hairs that form a structure similar to that of a forest. The hairs rise initially at an angle that is almost perpendicular to the feather surface but then bend in the direction of the flow to form a canopy with interlocking barbs at their tops—cross-fibers.

In their experiments, the researchers suspended mesh fabrics, which were designed to mimic the effect of the canopy, over sandpaper to create the “roughness.” They also simulated air flows using the Virginia Tech Wall-Jet Wind Tunnel.

The group concluded that the use of a unidirectional canopy, with cross-fibers removed, suppressed the noise-producing surface pressure without producing the high-frequency self-noise of the fabric canopies. They then used 3D printing to fabricate small plastic “finlets” that can be attached to an airfoil (or wing). The finlets can be retrofitted to an existing wing design and combined with other noise-reduction strategies to achieve even greater noise suppression.

“The most effective of our designs mimics the downy fibers of an owl’s wing, but with the cross-fibers removed,” says Jaworski. “The canopy of the owl wing surface pushes off the noisy flow. Our design mimics that but without the cross fibers, creating a unidirectional fence—essentially going one better than the owl.”

The research is funded in part by the U.S. Office of Naval Research.

Story by Lori Friedman

Posted on: