“In order for big schools like Lehigh and Ohio State to work together, there needs to be better methods of communicating and sharing data, and solving these problems together. The NHI enables us to bridge and develop new technologies that can help us communicate a lot more effectively,” said Marvel.

Added Harmer: “When we started the NHI Initiative, [our goal was] to create something new and exciting, which we have with this new idea of creating a modern way to interact with scientific instruments.”

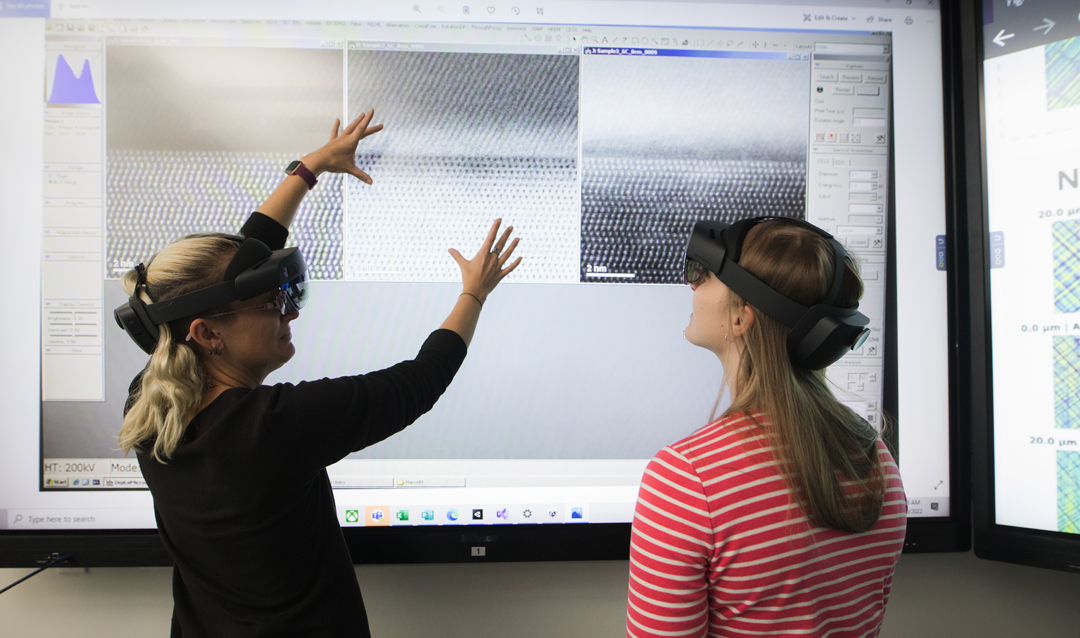

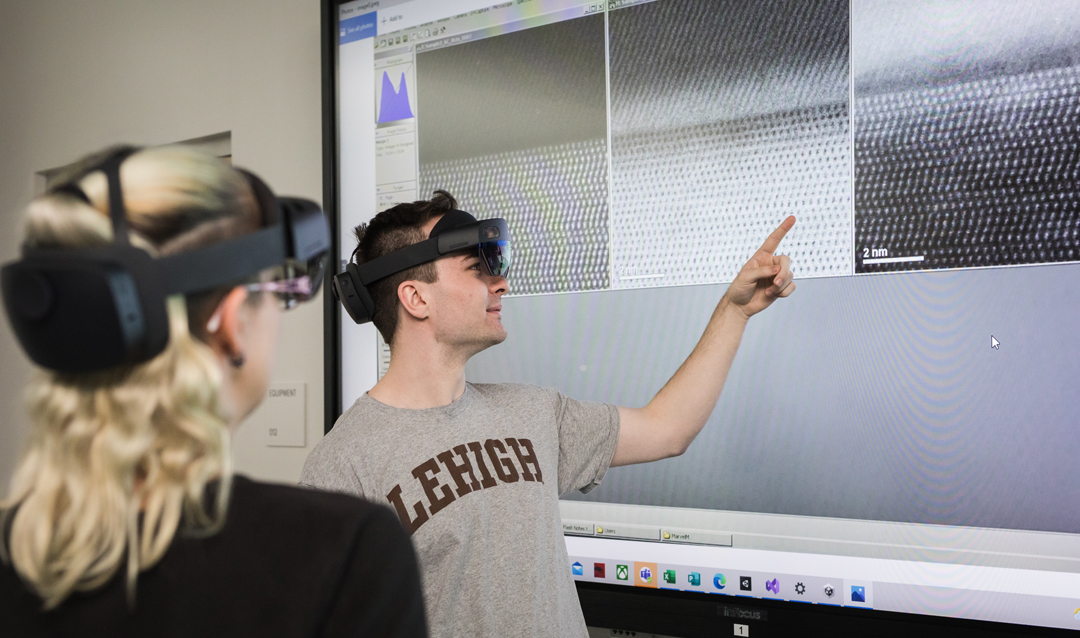

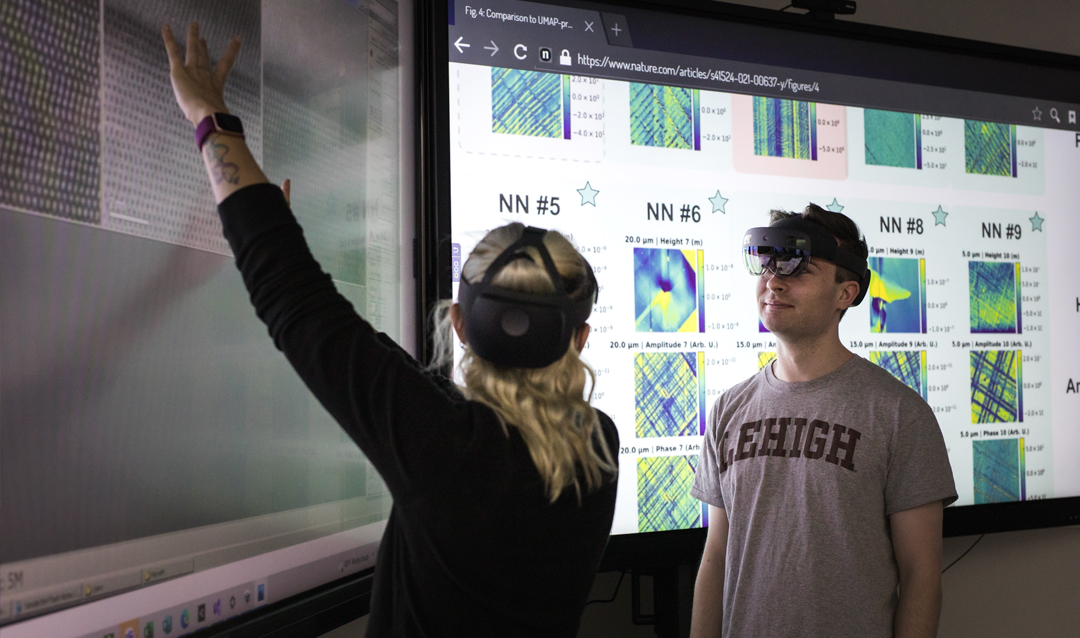

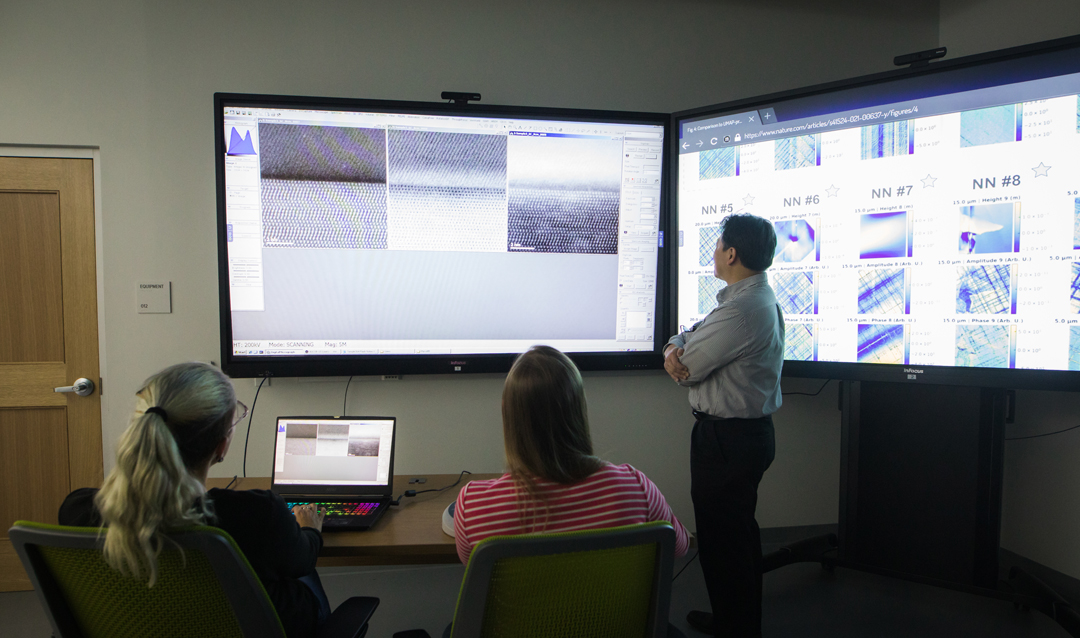

The NHI Lab includes a Visualization Lab with six 98-inch touchscreens, virtual and augmented reality interfaces, and controls that allow secure remote access to electron microscopes located at Lehigh and in Ohio State’s Center for Electron Microscopy. Ohio State’s lab will have similar controls to allow researchers there to access Lehigh’s microscopes. This approach addresses two problems: the physical distance between researchers and the number of individuals who can access a piece of equipment at once—which, in the case of an electron microscope, is currently limited to one or two individuals in a very small space. The team plans to extend this technology to other types of instrumentation at each university, such as equipment used for mechanical testing, 3D printing, and simulations, and to enrich these remote experiences with augmented reality.

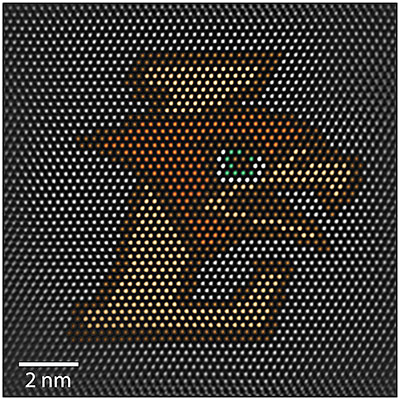

This project, the team writes in its proposal, will provide “easy access to over 20 separate electron microscopes, as well as other experimental tools of data collection,” producing “an unmatched collaborative infrastructure.”

The new facility also includes a “lab within a lab”: a human observation lab in which cognitive scientists can track, using a system of cameras and software for observation of eye gaze and human behavior, how researchers work as a team and how they interact with scientific instruments. These observations will help improve the research experience by identifying potential barriers to accelerate scientific discovery, and the team will use this information to develop a framework for an artificial intelligence user assistance capability called the Buddy System.

“We have modern technology as an assistant to accomplishing the goal of scientific research,” Harmer explained. “So it becomes your ‘buddy,’ much like a soldier might refer to the AI technology that they're wearing as their ‘buddy’ in a social setting. Buddy is an invisible assistant that's able to do all these amazing things to help us, to prompt us about what we might want to think about doing next in our experiments, and prompt us on how we might interpret some results. It can help guide us and to speed up the process of doing research.”

Marvel likens Buddy to KITT, the talking car of television’s “Knight Rider” fame, or Apple’s Siri and Amazon’s Alexa: a non-human, real-time assistant that makes human tasks easier.

“The Buddy System will streamline data collection by making data collection/analysis more efficient, and therefore increase the speed with which new alloys can be designed and developed,” the team wrote in its proposal.

This responsive user interface will extend into applications using Microsoft HoloLens 2 mixed-reality headsets: HoloBuddy™, an interactive application for microscope operation that would allow multiple users wearing headsets to experience what the microscope operator is seeing in an “augmented workspace”; HoloCollaborations™, which will integrate HoloBuddy and enable remote collaboration; and HoloMicroscope™, an educational app that will teach new users how to operate electron microscopes, taking them “inside” the instrument for deeper understanding.