Engineers open a wide window on the world

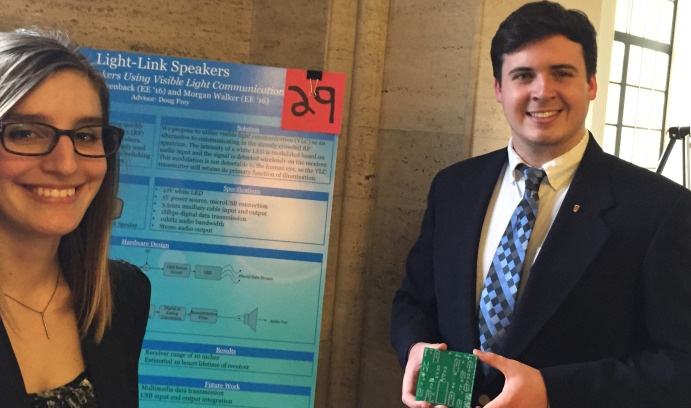

The Light Link Speaker System, conceived and assembled by Suzanne Scheckenback and Morgan Walker, uses light signals from ordinary LEDs to transmit data wirelessly. The project was one of 33 completed by electrical engineering and computer engineering majors in the Senior Design course.

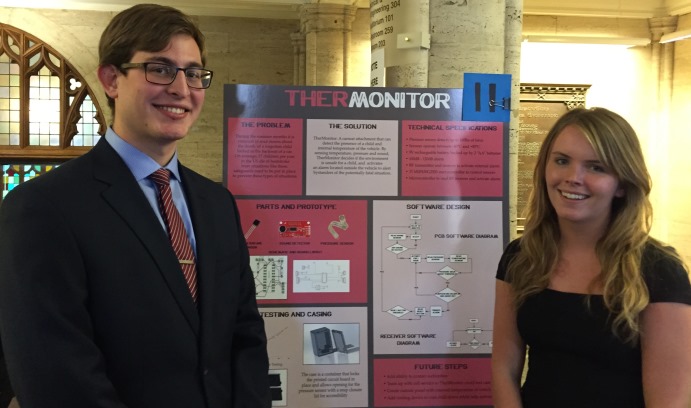

Inside a car whose windows are rolled up, says Elizabeth Durkin ’16, the air can heat quickly to temperatures that are deadly to an unattended child. According to the website noheatstroke.org, an average of 37 babies each year die of child vehicular heatstroke.

Durkin, who is completing a B.S. in electrical engineering, and Adin Greenwald ’16, a computer engineering major, have designed a device called Thermonitor that detects the presence of a child who is left unattended in a car and then triggers an alarm to warn passersby.

They displayed Thermonitor recently at the annual presentation of posters by students in ECE/CREG Senior Design, a two-semester laboratory course that is required of electrical engineering and computer engineering majors.

Thermonitor uses three sensors to measure and track sound, pressure and temperature. When the sensors detect the lack of sound along with the presence of a baby in the car, they activate the alarm.

“The sound of our alarm is so different from a typical alarm that it should cause people to stop and check,” says Durkin. “It’s horrifyingly loud. When we tested it in the lab, we warned everyone first, but they still jumped.”

The sensors trigger the alarm when the temperature inside a car reaches 70 degrees Fahrenheit. “You have to catch this early,” says Durkin. “The temperature inside a car can rise 29 degrees in less than half an hour. When a child is left in a car seat, immediate intervention is necessary.”

No need for a step-by-step guide

Durkin is also completing a second B.S. with a finance concentration in Lehigh’s Integrated Business and Engineering honors program (IBE). After graduating, she will take a job with in investment banking with Stifel Financial Corp. in New York City.

“This project is very hands-on,” says Durkin. “It’s the first time I’ve had to solve a problem myself; there was no step-by-step guide. And there are so many standards with baby car seats. You have to be very careful not to alter any part of the car seat. We’ve done extensive research and testing.”

The project that Durkin and Greenwald worked on was one of 33 completed by 67 students in the Senior Design class. The poster presentations were held May 6 in the lobby of Packard Lab.

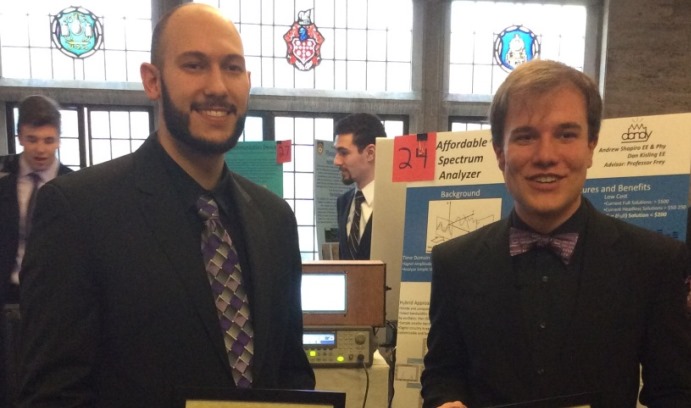

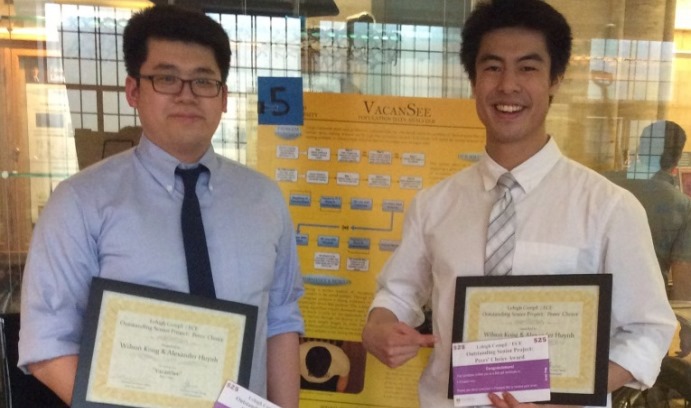

A panel of seven judges from industry graded the projects for poster design, presentation and implementation. The judges awarded first prize to Daniel Kisling and Andrew Shapiro for their project, which was titled “Affordable Spectrum Analyzer.” The popular vote winners were Alexander Huynh and Wilson Kong for their project, “VacanSee.”

Two pairs of students had previously won prizes at the IEEE Morton Student Paper Contest, which was held April 21 at Wilkes University. Charles Drazba and Nick Trivelis took first place for “The Magnetic Wall Scaling Robot” (also called “The Magnet Monkey”), and Suzanne Scheckenback and Morgan Walker took second for the “Light Link Speaker System.”

The students in the Senior Design class said that working on their projects had required them to apply what they learned in their other courses, to be resourceful and to venture into other engineering fields.

“We’re electrical engineers, but there’s a lot of mechanical engineering work required with the Magnetic Monkey,” said Drazba. “We had to spend a lot of time learning 3D printing. Neither of us had had any experience with that.”

A monkey that climbs walls

The Magnetic Monkey, said Drazba, is designed to climb autonomously up walls and along floors, ceilings and magnetic surfaces. The project’s goal is to show that robots can provide an efficient, cost-effective and safe alternative to human labor when performing maintenance tasks in construction sites, factories, machine shops and other industrial environments.

So far, said Drazba, the monkey has no problem making its way along ceilings and flat surfaces. But challenges remain with the servo-driven arms that pull the robot in desired directions.

“We have the ceilings and flat surfaces down,” he said. “But the servo can’t provide the torque yet that’s required to defy gravity and go up a wall. It’s a question of hardware and equipment. A stronger servo might do the trick; so could an alternate navigation scheme. We need more money to do tests.

“This project has helped me realize that when you’re designing something, there are a lot of things to consider. If you’re just focused on software or robotics, you would not expect this.”

After graduation, Drazba and Trivelis will both enroll as graduate students at the University of Pennsylvania. Drazba will also work full-time for LimnTech Scientific Inc., which designs and manufactures machine vision systems for the roadway marking industry.

From wi-fi to li-fi

Scheckenback is confident that she and Walker established a sound proof of concept of the Light Link Speaker System, which uses light signals from ordinary LEDs to transmit data wirelessly.

“There’s definitely still room to grow,” she said. “It would be great to have a few more weeks to work on the project, but I think we’ve established a really good proof of concept.

“This class gives us a great idea of what it’s like to be an engineer. You come up with an idea, you do the research and make your first design, and you do the simulation and the prototypes. Then you have to go back and make changes. There’s always room for improvement. Engineering is very recursive—you figure out what’s wrong and try to improve on it.”

Scheckenback has had several internships with Lutron Lighting of Coopersburg, Pa., and will join the company full-time after graduation.

The Light Link Speaker System, she said, utilizes an LED whose brightness blinks on and off too rapidly to be detected by the human eye, which instead sees a constant glow. A photosensitive device on the system’s receiver converts the blinking into a data signal.

The system is an example of light fidelity, or li-fi, an emerging technology that transmits data wirelessly using light waves, unlike wi-fi (wireless local area networks), which uses radio waves.

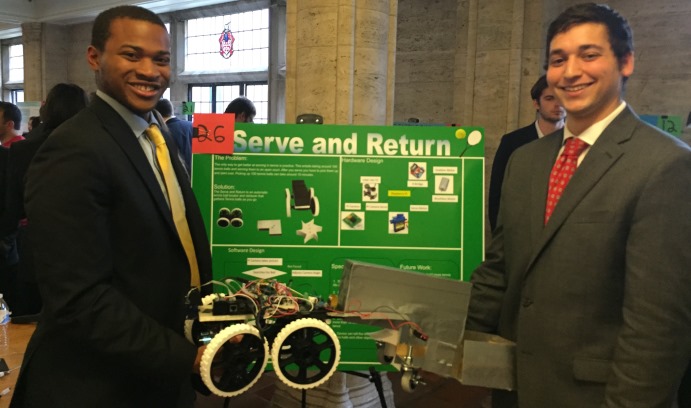

Two other seniors—Jackson McDermott, a computer engineering major, and Schuyler Parsonnet, an electrical engineering major—designed and built a robotic system capable of autonomously searching for, finding and picking up loose tennis balls on a tennis court. The project blended robotics, image processing and mechanical engineering.

“We bought a remote-control car and stripped it,” said McDermott. “Then we changed the wheels so a tennis ball could fit underneath. We also 3D-printed the wheel hubs and the pinwheel. We put a camera on the front of the car to look for the tennis balls and do image processing. The camera takes normal photographs, which we converted to HSV [hue, shade, value] to make it easier to detect the tennis ball’s color.”

“There was a lot of mechanical engineering involved,” said Parsonnet. “We had to learn as we went along.”

In addition to retrieving tennis balls after a practice session, the device could be reconfigured to pick up golf balls from a driving range, McDermott and Parsonnet said.

“The Senior Design course definitely helped me set goals and meet deadlines,” said McDermott, who will take a job after graduation as a software engineer with Fidelity Investments in Boston.

Parsonnet, who is also completing a B.S. in IBE with a concentration in finance, said the course helped him land a summer internship with an investment bank.

“It’s great to be able to learn something brand new from scratch and figure out how to do it,” he said.

The Senior Design course is taught by William Haller, professor of practice in the department of electrical and computer engineering, and Liang Cheng, associate professor of computer science and engineering.

Posted on: